In other words, blasting below or above this range does not meet the product test requirements, and the test pressure of this burst point should be recorded. The test difficulties are: the air tightness tester’s extraction of negative pressure requirements to meet the second test requirements, the pressure rate can be adjusted, and the pressure explosion should be completed within the set range, can not exceed the range.

The product is required to break instantly when the vacuum is extracted or the pressure is applied to a certain pressure range. It can be divided into negative pressure rupture test or positive pressure rupture test. slope, can be set, such as 10kPa /min: the test requires that the pressure rise can be adjusted in proportion to the time. The principle of positive pressure withstand test is similar to that of negative pressure withstand test, that is, the initial positive pressure is set at any pressure, such as 0 pressure or 10kPa.

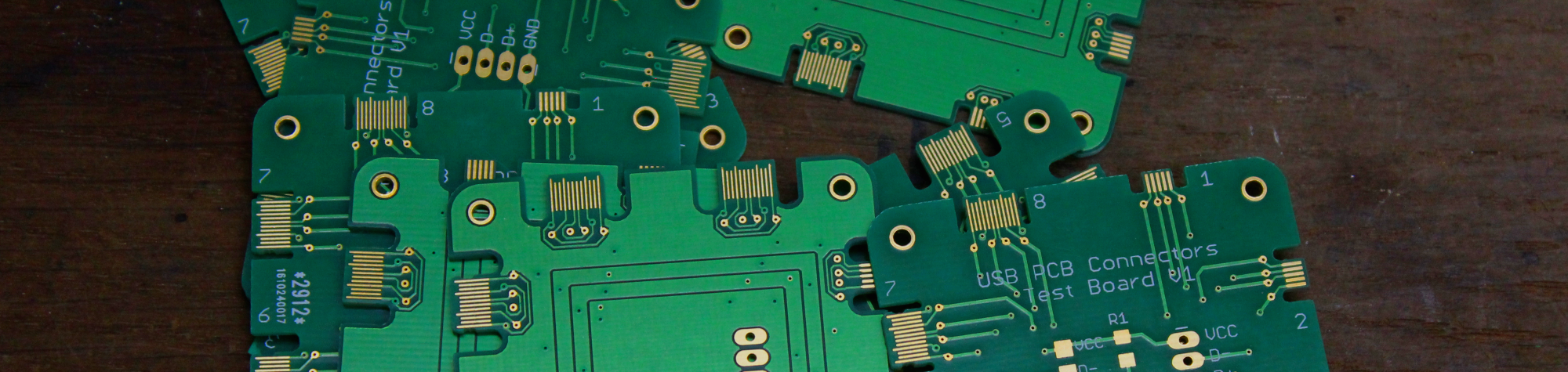

#AUTO CONNECTOR TESTING GENERATOR#

Initial pressure started from zero, the ability of the vacuum generated by the vacuum source (vacuum generator or vacuum pump), vacuum after vacuum source through the pressure regulating valve is fixed, the speed of the instant pressure extraction is only from 0 to fixed pressure regulator set pressure, do not have control the extraction pressure and the ability to time into different ratios.

#AUTO CONNECTOR TESTING MANUAL#

As we all know, the sealing tester or the air tightness detector is equipped with manual or electronic pressure regulating valve, which can only be adjusted according to the set pressure. The difficulty in this test is that the tightness tester or leak detector is required to be able to set the starting pressure for the extraction of negative pressure value, such as starting from 0, of course, it can also be required to start from -10kPa, and the extraction rate can also be set, and can be changed. For example, set the vacuum extraction to -50kPa and the extraction rate is 10kPa /min. The test requires the selection of precise proportional control valve set, from the initial pressure 0 value in accordance with a certain vacuum rate to vacuum the product, vacuum time and vacuum degree of the proportion of the requirements can be adjusted. Pressure test can be divided into negative pressure test and positive pressure test. Test products with leakage rate less than 1cc/min or with higher requirement less than 0.5cc/min are qualified products. Generally, it is required to seal the product with a fixture under positive pressure or negative pressure of 10kPa to 50kPa.

It is required to test the tightness of the connector under vacuum or positive pressure. With the development of the car more and more tend to be multi-functional, intelligent, the design of the car connector is also facing more and more difficult, so the car connector in the seal test, must pass the corresponding seal test to pass, then you know what is the seal test of the car connector? When it comes to automotive electrical connector system performance standards, that is to comply with the USCAR-20 standard, USCAR-20 automotive connector must be safe and reliable throughout the life cycle, so as to provide users with basic safety performance. What are the requirements for automotive connector seal testing?

0 kommentar(er)

0 kommentar(er)